FAQ's

Here are some common questions about our products.

Pipemark ID Tapes : Available in 150 mm , 275 mm and 450mm* widths, with roll lengths of 33 m. All Pipemark ID Tapes comply with BS 1710:2014 using BS4800 colours.

(450mm* tapes are supplied as a set of 3 x 150mm tapes).

The tapes are made from self-adhesive plastic materials with a clear permanent self- adhesive. They are printed using proprietary UV+ inks, ensuring high light-fastness and durability

Indoor tapes operate effectively between –20 °C and +80 °C, and are resistant to water, oils, and chemicals

Pipemark tapes are manufactured from self-adhesive plastic with a clear permanent self- adhesive, offering high durability and strong bonding

Yes. Pipemark indoor tapes conform to BS 1710 and BS 4800 colour standards and are printed with UV‑stable inks for long-term legibility.

Apply tape onto a clean, dry, smooth surface. The tape can be rotated 180° to indicate flow in either direction. Pipemark ID Tapes include a release liner to protect adhesive until installation. The Release liner should always be fully removed to ensure proper adhesion.

The Pipemark Range includes hundreds of Tape variants to suit your installation. If you can’t find the tape you require in our Stock List. View our Made To Order (MTO) list – we will also print to your exact Specification if you can’t find what you require.

Yes Pipemark OUTDOOR – is available in our stock and MTO range.

Absolutely. We offer bespoke printing to suit your specification, including custom colours, directional arrows, text – we can even add your company logo if required. Contact us for custom orders.

In-stock indoor and outdoor versions often ship same day if ordered before 12 pm, with free shipping in the UK Mainland on orders over £50.

We now ship Worldwide – see our ‘Shipping Information’ link for pricing / details – Or contact our team.

Returns accepted within 30 days under our returns policy.

Relevant downloads available on the site include: Indoor and Outdoor specification sheets, application instructions, Pipemark warranty statement, Pipemark Leaflet and boxed duct triangle specs etc.

PRODUCT LIFE CYCLE ASSESMENT

Our Product Life Cycle Assessment (LCA) outlines the environmental footprint of Pipemark’s industrial marking solutions. From energy used in production to water consumption and CO₂ emissions per square meter, this assessment reflects our commitment to transparency and sustainability in every roll of pipe marking tape we deliver.

Energy Use

Our Pipemark labels are manufactured using 9.3 megajoules of non-renewable energy per square metre.

This includes everything from raw material extraction to production — ensuring full cradle-to-gate transparency. .

Water Consumption

Each square metre of Pipemark labelling uses 6.3 litres of net fresh water during production.

We monitor this closely to reduce environmental stress and support responsible water use.

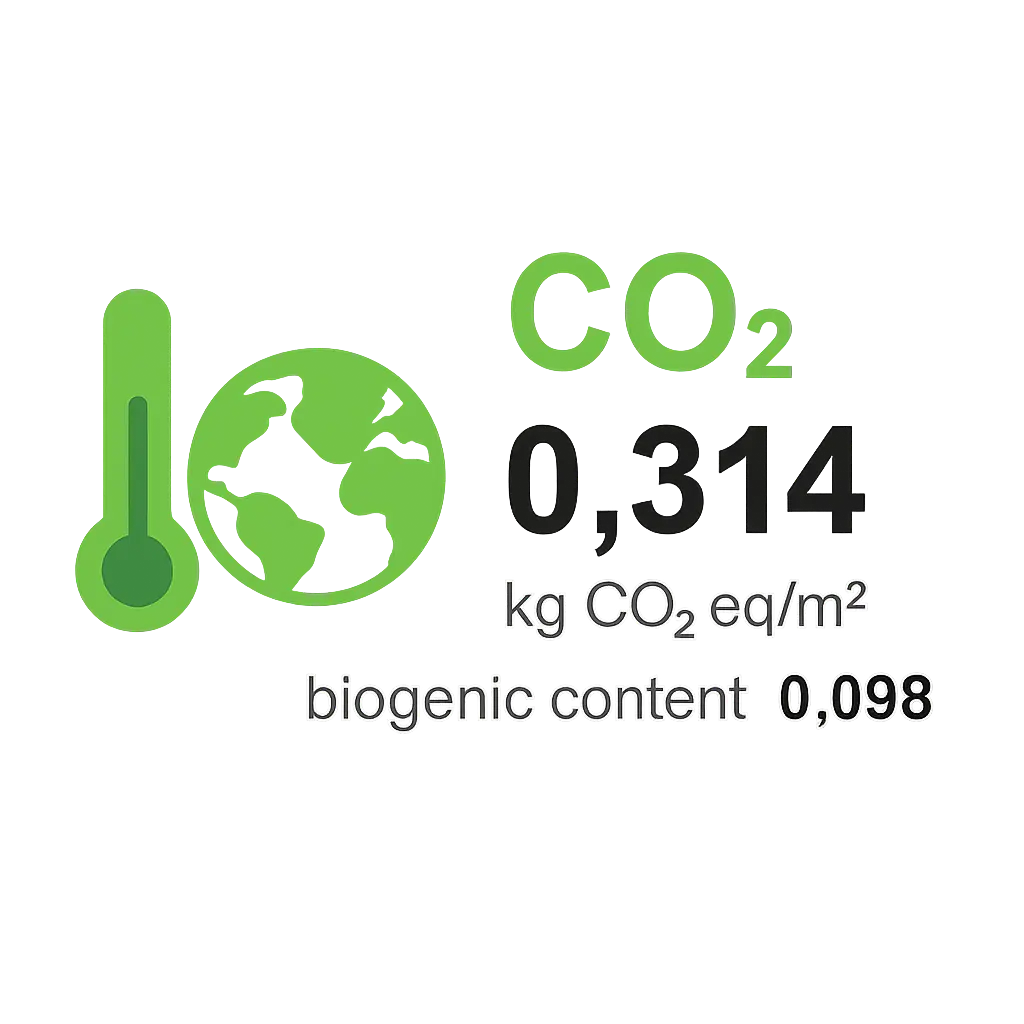

Carbon Footprint

Pipemark products release just 0.314 kilograms of fossil CO₂ per square metre.

This figure excludes biogenic sources to give an accurate climate impact.